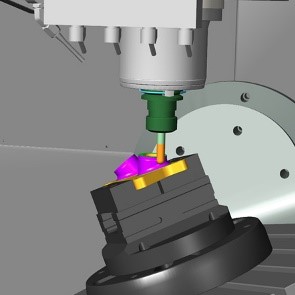

AM (Computer Aided Manufacturing) best symbolizes our mastery of new technologies :

For the uninitiated, it involves carrying out mechanical manufacturing on a numerically controlled machine tool connected to a computer program using which simulated programs are produced on a computer. A post-processor placed in the PC automatically generates the ISO program lines understandable by the machine tool. Interfacing with the design office then becomes optimal : The drawings are downloaded to the CAM station in order to generate production programs. manufacturing intended to be carried out by the numerically controlled machine tool.

The workshop has four CAM stations equipped with MASTERCAM software associated with three machining centers and a 3-axis numerical control lathe. The powerful ULTIMAX 3D conversational system also equips one of the three machining centers

The advantages of CAM and digital :

- high precision in positioning and repeatability

- production of parts with complex shapes in 3 dimensions

- BE-FAO interfacing for better reliability and substantial time savings

- working in hidden hours

- recall of recorded programs for later production

- machining simulation in virtual mode before final production launch